3D-Printing |

HOME |

We thrive on thinking about new 3D printing technologies. Here we give you a glimpse on our findings.

|

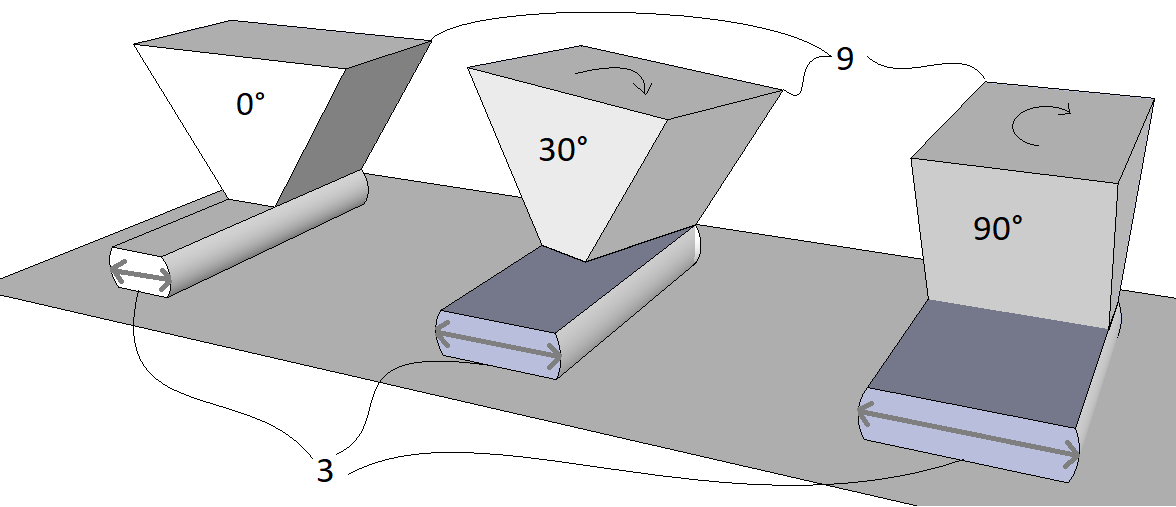

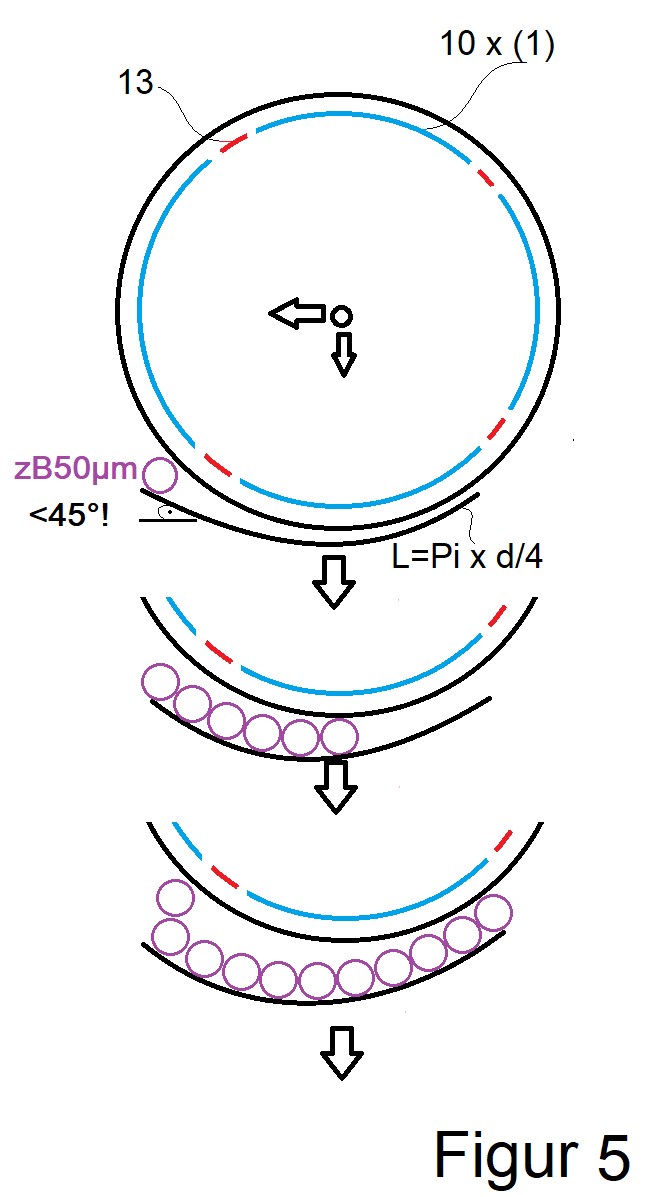

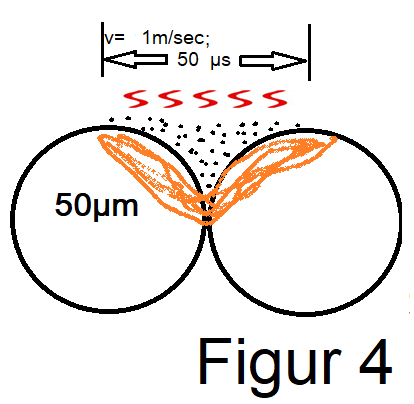

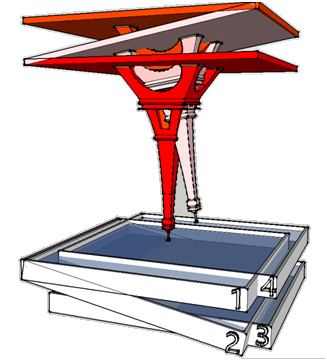

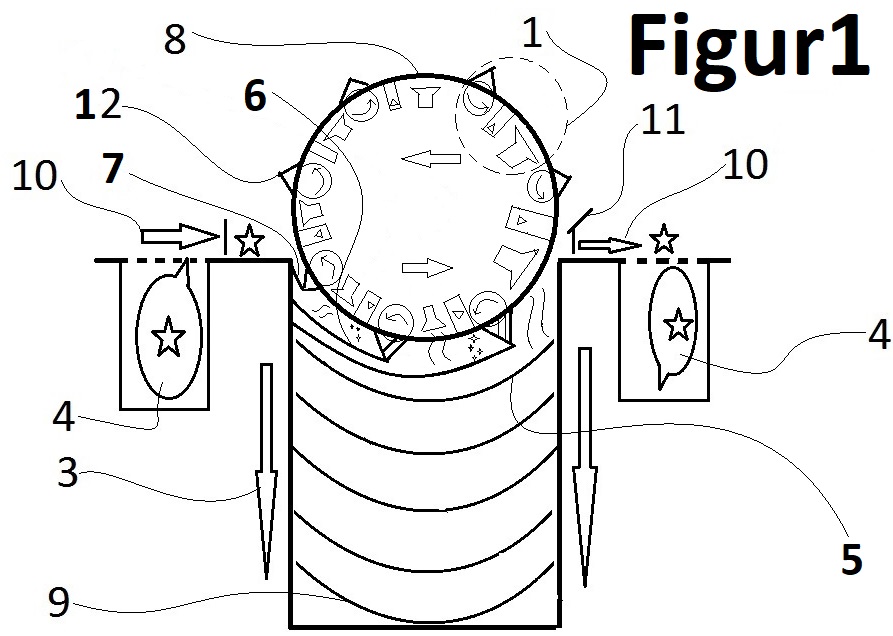

Peeling Mechanism for 3D SLA Printer DE102014114333 A1 |

|

|

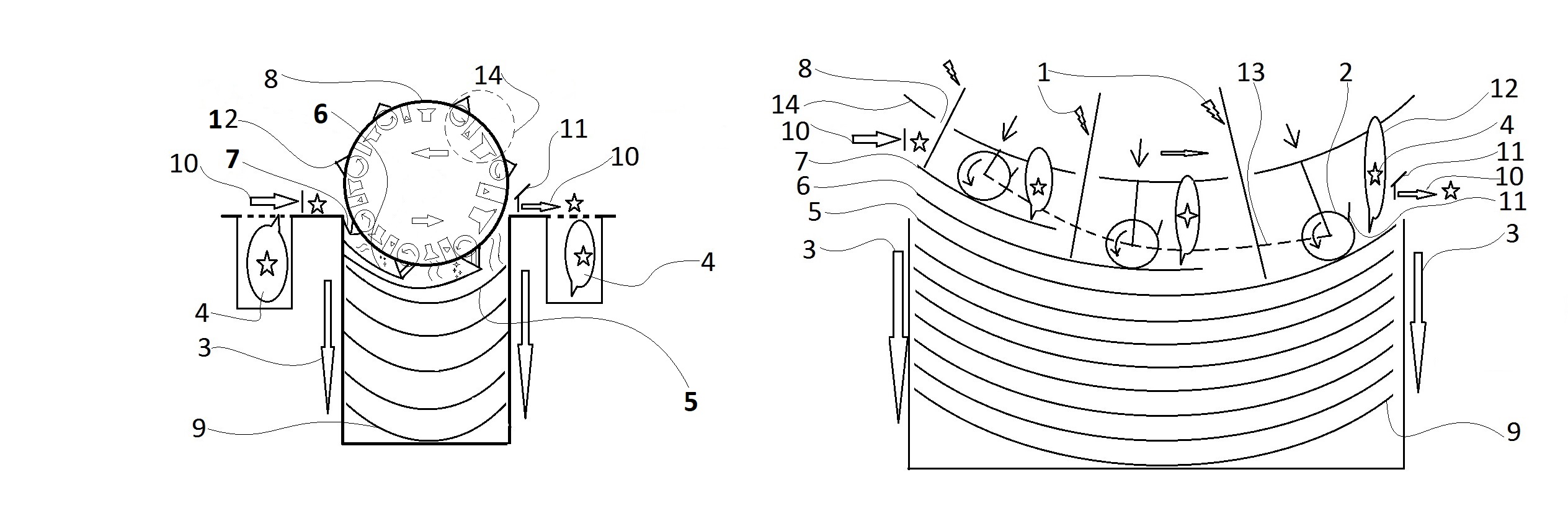

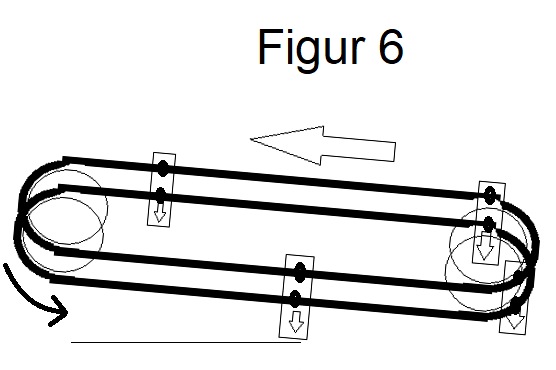

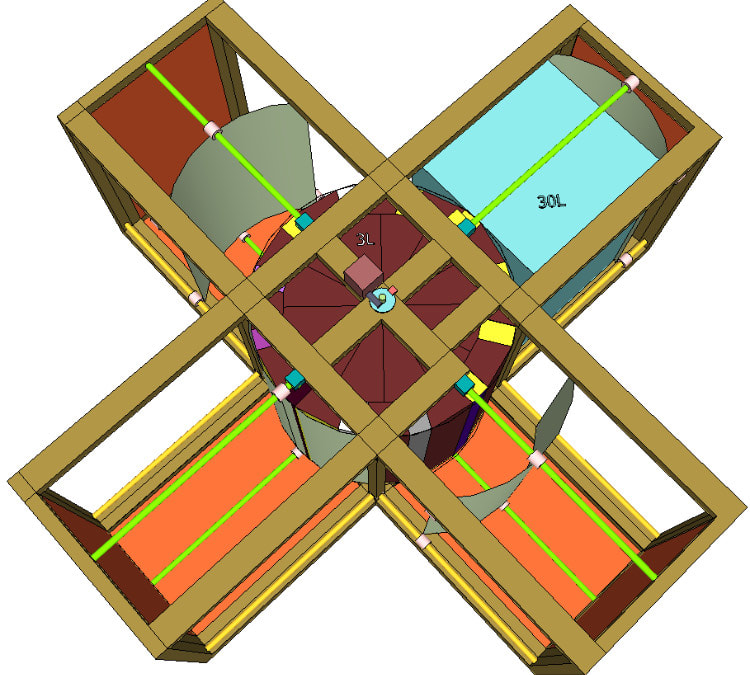

Drum Printer E102014019392.6 |

|

|

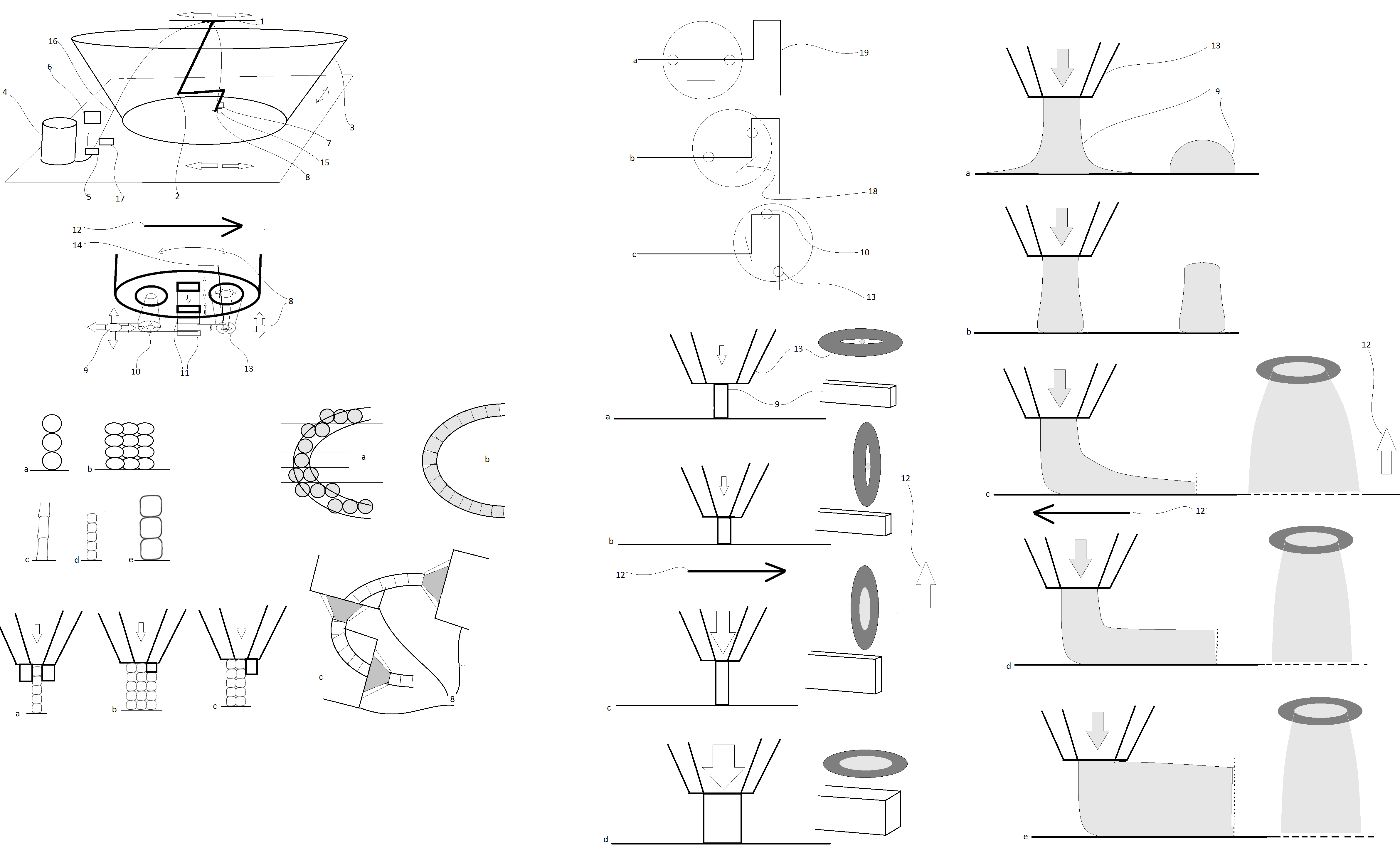

Giant Printer -Turning Valve Print-head DE102015016823.1 |

|

|

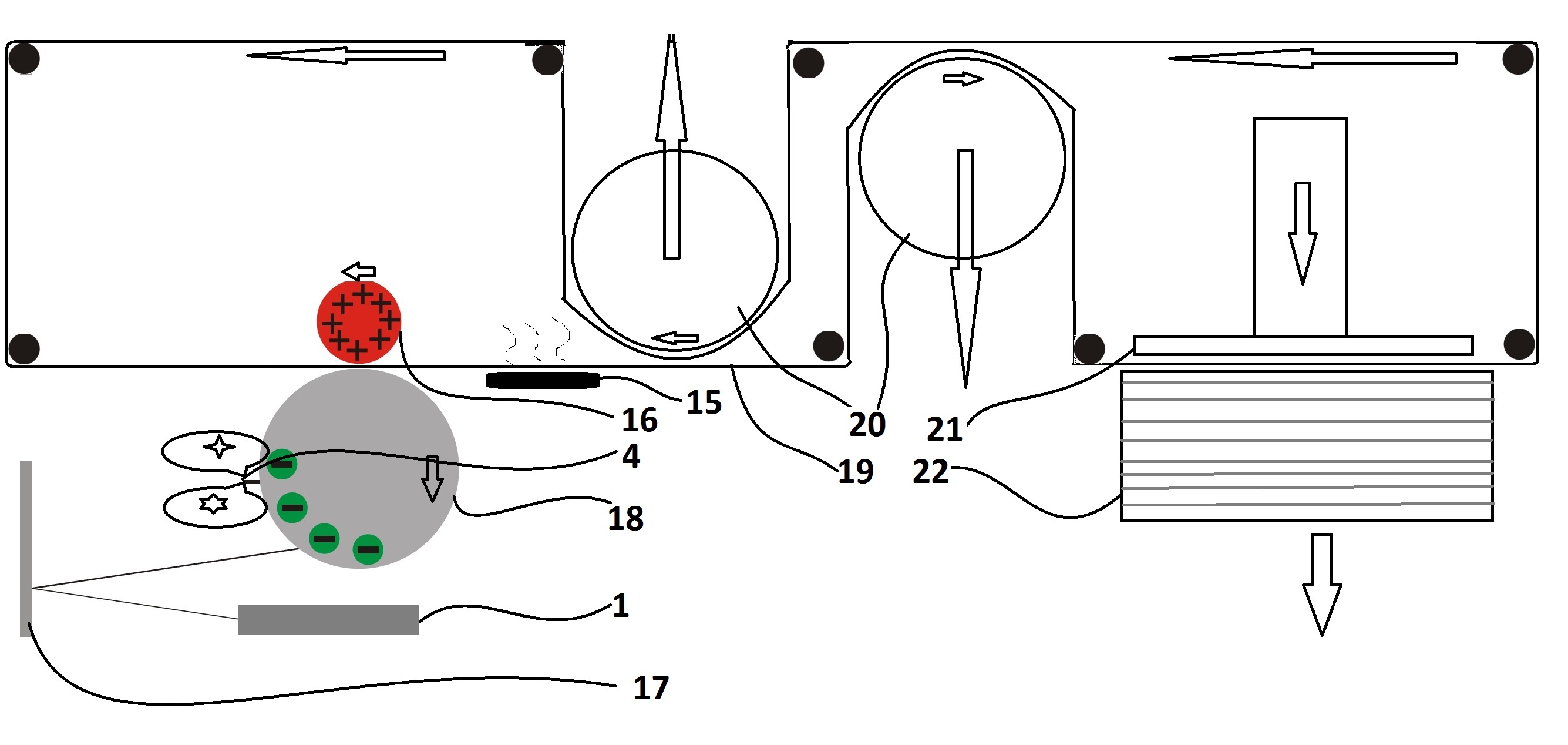

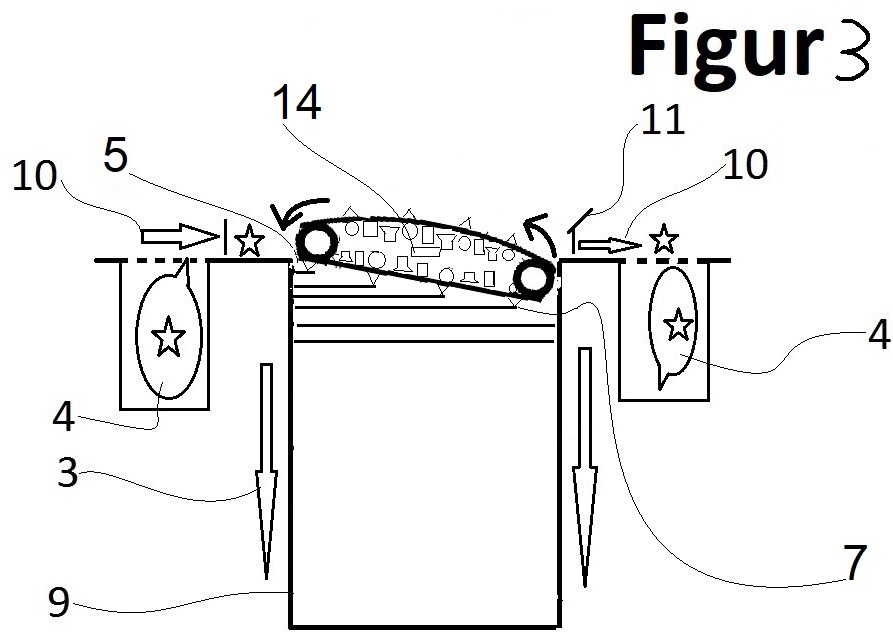

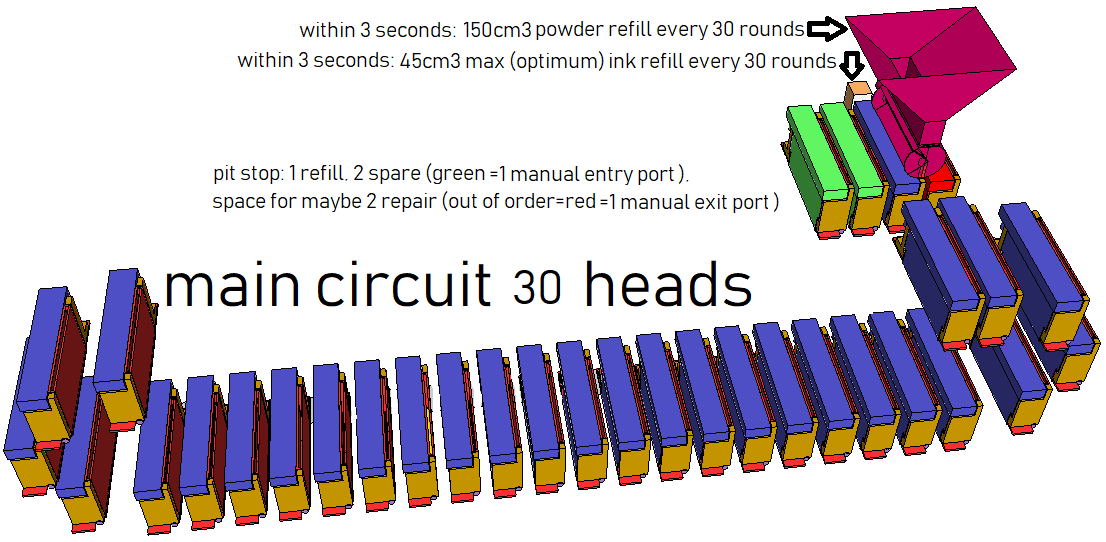

Fast and Continuously Printing Full Color Multi Material 3D SLS Printer DE102016002598.0 |

|

|

feststofftrommeldrucker DE102016015617.1 |

|

|

variable fdm düse DE102017012061.7 |

|

|

continuous hss print DE102018006091.9 |

|

|

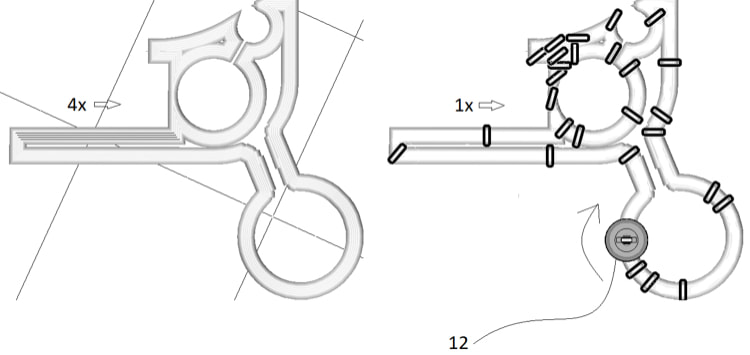

Hyperfusion 1 DE102018008594.6 |

|

|

Hyperfusion 2 carousel DE102018010015.5 |

|

|

Hyperfusion 3 hot carousel DE102019002299.8 |

|

|

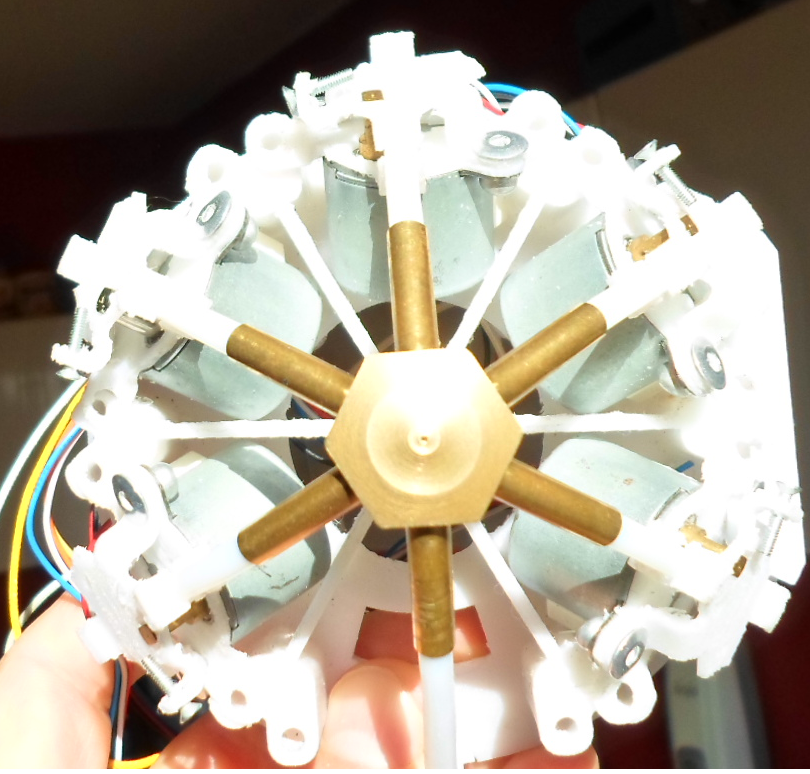

6-Filament Print Head

|

|

|

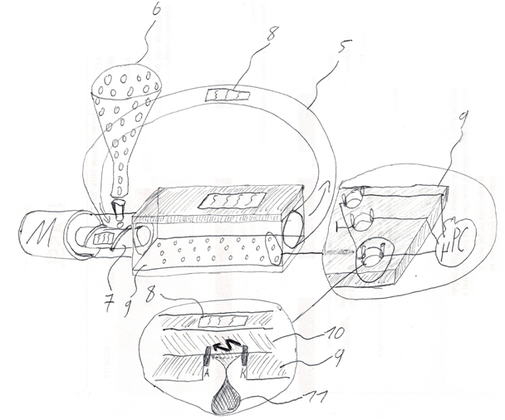

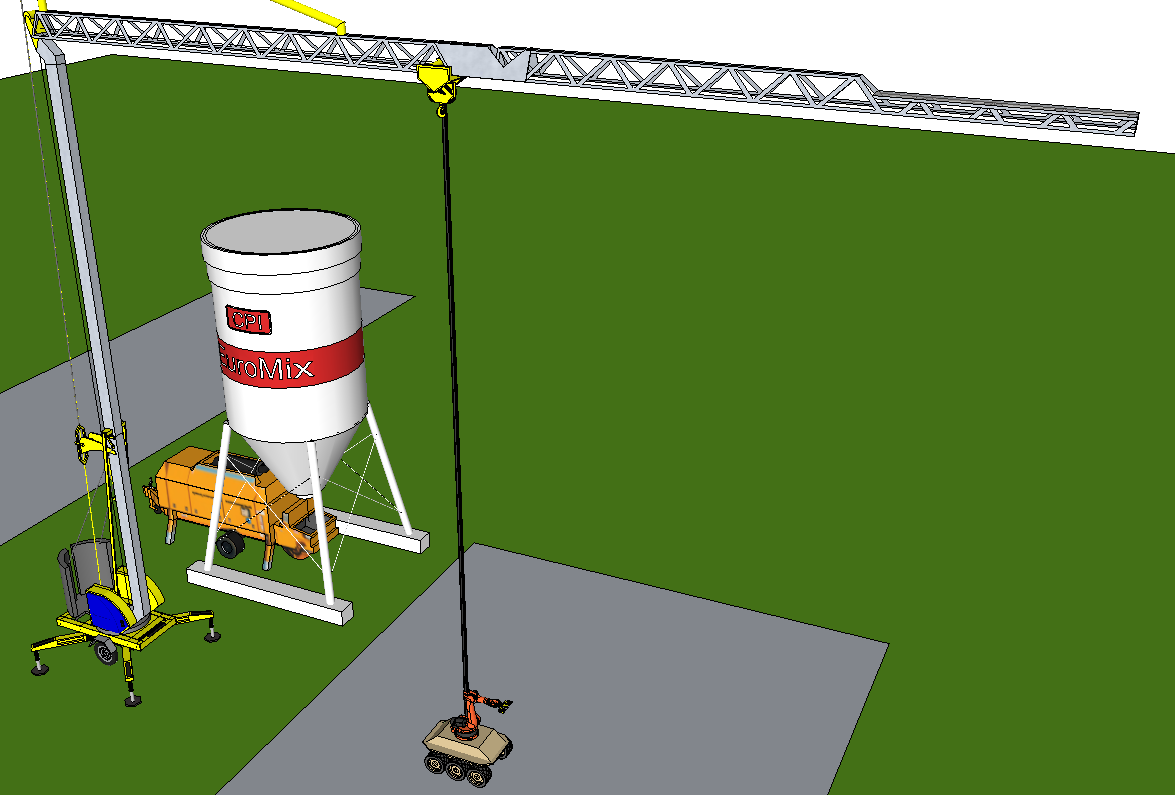

House Printer

|

|